About Wet Earth®

Purpose

Wet Earth's purpose is to provide complete solutions to satisfy our customers requirements.

About Us

Since 2003 Wet Earth has been selling solutions to mining companies. Our focus has and always will be finding the best solution to customers requirements. We consider ourselves unique in that we are brand independent so we can select the best products and offer a range of solutions to our customers.

We can provide a full service solution to customers from electrical, hydraulic and mechanical design and manufacture through to installation supervision and commissioning. All our products can be manufactured or customised to suit our clients specific requirements.

Our key areas of expertise and experience are controlling mine dust, evaporating waste water and general mine water and spray systems.

Committment to Quality

Wet Earth has a committment to providing our customers with quality products and solutions. This committment is illustrated by our ISO 9001 Quality Certification.

Innovation

Wet Earth is committed to finding or developing the best solution for our customers. The following demonstrate our committment to sourcing and developing innovative solutions for our customers:

- 2008 became an exclusive agent for Fog Cannons and introduced this technology to Australia;

- 2010 imported the first Evaporation Cannon into Australia and introduced this technology to Australia;

- 2012 developed the first super concentrated liquid polymer dust suppression product in Australia;

- 2016 developed a high impact hose nozzle to clean iron ore chutes for BHP;

- 2020 designed a new base for the Skipper Washdown with BHP & Rio Tinto to prevent dust and water ingress;

- 2022 became a distributor of the DSI dry fog and wind fence systems; and

- 2024 designed a modular portable wind fence system.

Our Customers

Wet Earth® customers include:

- BHP;

- CITIC Pacific;

- CS Energy;

- Fortescue Metal Group;

- Glencore;

- Hillgrove Resources;

- Jellinbah;

- MMG;

- Newcrest Mining Ltd;

- Nystar;

- Peabody;

- Pilbara Minerals;

- Rio Tinto;

- Sibelco;

- Thiess;

- Whitehaven Coal;

Recent Projects

The following projects illustrate our capabilities

Jellinbah Mining - ROM Hopper Dry Fog (2024)

A Dry Fog system to suppress dust when trucks are dumping into their ROM Hopper. A PLC controlled system integrated into their mine management system.

Wet Earth provided the system design, dry fog system, water tank, pump and filtration skid, air compressor and air receiver, electrical distibution board and commissioning.

The following image illustrates the ROM Hopper being pre-filled with fog prior to dumping.

BMA / Whitehaven Daunia - ROM Hopper Dry Fog and Wind Fence (2024)

A Dry Fog system to suppress dust when trucks are dumping into their ROM Hopper. It also included wind fences to protect the ROM Hopper from wind to prevent wind negatively impacting the Dry Fog performance. It is controlled by the mine management system.

Wet Earth provided the system design, dry fog system, wind fence system, water tank, pump and filtration skid, air compressor and air receiver, electrical distibution board and commissioning.

The following image illustrate the ROM Hopper being prefilled with fog prior to dumping.

CSR PGH Bricks - Stockpile Spray System (2024)

A sprinkler system to prevent dust lifting off their stockpiles. PLC with touch screen controlled system using bus style control (2 wire) to the valves for 14 sprinklers over 1.6km.

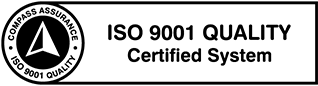

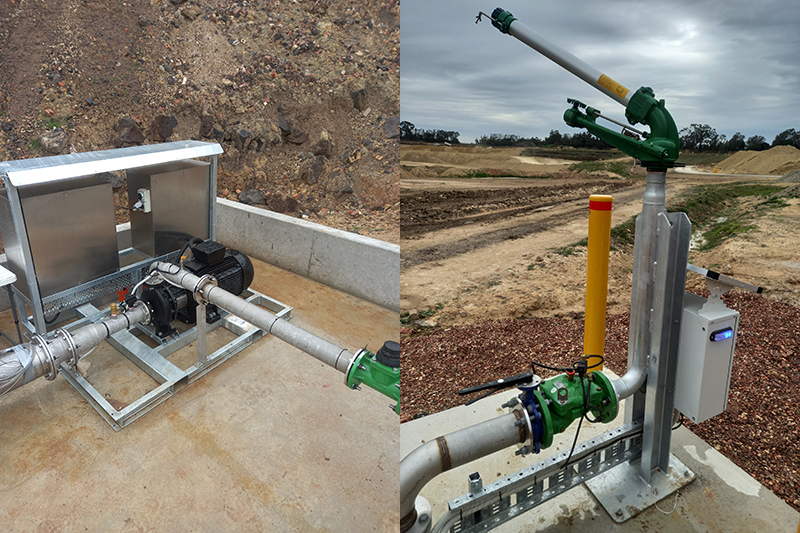

Wet Earth provided the hydraulic design, sprinkler stand/support design, sprinklers, valves, pump skid, control system, control programming and commissioning.

The following image illustrate the pump skid and the sprinkler, valve support configuration.

MMG Dugal River - Wind Fence (2023)

A 130m long and 10m high wind fence to protect the the ROM Pad from wind to reduce dust carried from the ROM pad.

Wet Earth provided the wind fence layout design, support system structural design, wind fence system supply and installation supervision.

The fence can be seen on google maps.