Wind Fences

Wind erosion causes an estimated 30 percent of stockpile

dust emissions. Reducing the wind speed over the stockpile

results in less dust. DustTamer Wind Fence material is designed to reduce wind speeds up to 90 percent within the

sheltered area.

Why a Wind Fence?

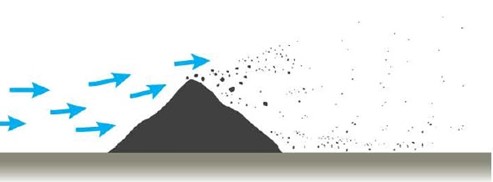

Wind blows across the surface causing particles to move and ultimately lift off. This airborne dust then travels where it can be inhaled or deposited for future lift off.

The size of particles that lift off is related to the wind

speed. The following table provides a theoretical guide of wind speed required

to lift off particles of different sizes and densities. It is important to note

that the lift off of larger particles exposes more smaller particles to the

wind increasing the total volume of dust, particularly respirable PM10

particles.

| Material | Density | 1 Micron Particle | 10 Micron Particle | 100 Micron Particle |

| Coal | 800 kg/m3 | 0.8 m/s | 2.6 m/s | 8.3 m/s |

| Dirt | 1300 kg/m3 | 1.1 m/s | 3.4 m/s | 10.6 m/s |

| Iron Ore | 2200 kg/m3 | 1.4 m/s | 4.4 m/s | 13.8 m/s |

| Lead | 3200 kg/m3 | 1.7 m/s | 5.3 m/s | 16.6 m/s |

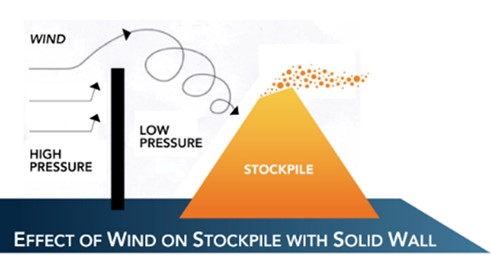

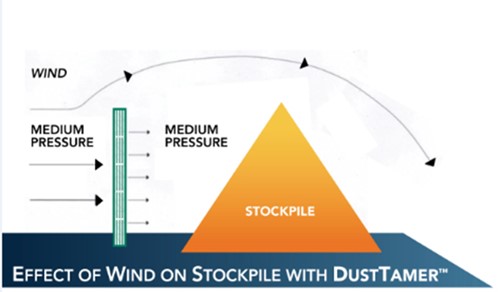

Why a Wind Fence and Not a Wall?

If a solid wall is used as a wind break, two different pressure zones are created as wind movement towards the wall increases. Impermeable materials such as a solid wall only deflect wind, not reduce it, creating a low pressure area in front of the structure which increases turbulence and causes more dust to lift off the surface.

If a porous material is used, high velocity wind that moves toward the stockpile is reduced as air passes through, equalizing air pressure on either side of the barrier. A Wind Fence which reduces the wind speed in the protection zone does a better job at preventing dust lift off.

DSI DustTamer Wind Fence Fabric

DustTamer Fabric is specifically designed for use as a wind reduction material. It is knitted from industrial grade woven polyester, resistant to UV rays, inclement weather, and temperature extremes. It’s unique ability to be stretched and tensioned to over 250 kg of pull prevents "flagging” of the material and consequential damage due to abrasion.

The fabric is 150cm or 90cm wide and is installed horizontally, spanning support columns as wide as 8m apart. DustTamer 6510 is 30% porous (90% wind reduction) and 6517 is 50% porous (75% wind reduction). The DustTamer material DOES NOT require any cable supports.

DustTamer fabric has been used for over 30 years as a wind

reduction tool. A study of this fabric’s

effectiveness was jointly conducted by the National Oceanic Atmospheric

Administration and North Carolina State University and published in the Journal

of Air Pollution Control in 1988.

Special Features of the DustTamer System

- ACE polyester fabric is highly resistant to the elements (same fabric as used for towing and lifting)

- Knitted design is so strong that it is self-supporting for spans up to 8m, no cables required

- Fabric can withstand very high wind loads without damage (in excess of 200 km/hr) therefore DustTamer will work in high wind conditions when you need it most

- Permanent installation with no maintenance required. The system is built to last for 20 years or more.

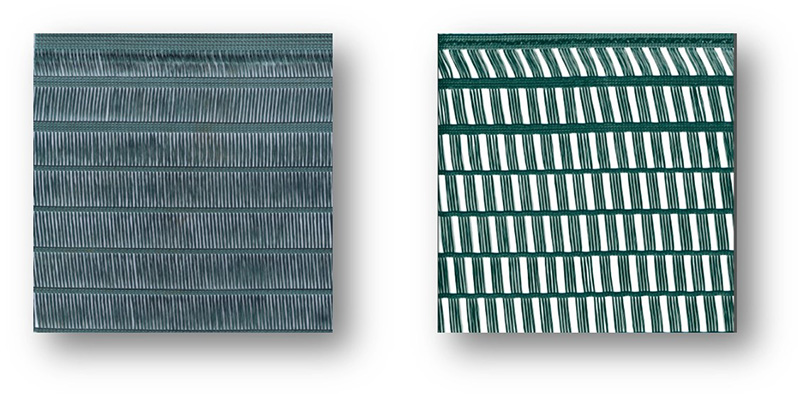

- Slotted fabric design is more effective than a basket weave style design. DustTamer is self-cleaning as the vertical filaments will move with slots 27mm long.

- Simple attachment hardware, no cables, heavy hardware or clips to install or maintain after installation due to stretching

- If damaged, repair is simple, requiring only the section and fabric run to be spliced into the fence

- Proven performance in all kinds of environments

Securing Mechanism

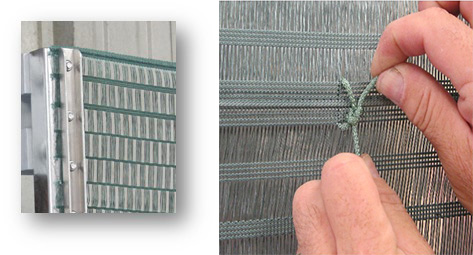

Stand-Off Brackets

We provide specifically designed metal brackets to "stand off” the fabric from the support columns. This prevents the fabric from coming into contact with the post. They also provide a material that is thin enough to allow self-drilling/tapping attachment screws to penetrate the metal without pre-drilling. This makes installation significantly easier when attaching the fabric to the support columns.

Lock Bars

Anodized aluminium lock bars are available in lengths that match the fabric width (90cm or 150cm). They are used to "pinch” the wind screen fabric against the stand-off brackets. The lock bars are pre-drilled to accommodate 15 #10 self-drilling/tapping screws per bar.

Attachment Screws

15 #10-3/4” long, self-drilling/tapping hex head screws are provided per lock bar.

Tie Wraps

Fabric ties are usually installed at 60cm intervals on centre to tie the fabric together. This prevents fabric wear between horizontal fabric runs.

Wind Fence Installation Photos