Dry Fog vs High Pressure Misting

Dry Fog and High Pressure Misting are used for similar applications such as suppressing dust in ROM hoppers, crushers, transfer points and ship loaders. They are used to suppress dust once it has become airborne. They are not used to wet material to prevent dust lift off (see NESCO Sprays).

For a given volume of water the smaller 4 micron droplet of the Dry Fog also results in 860 times as many droplets with a total surface area 9.5 times as large as the 38 micron droplet of the High Pressure Misting. This results in a significant improvement in dust capture capability particularly in the PN2.5 and PN10 size dust particles. In practice this results in Dry Fog dust suppression systems using significantly less water than a High Pressure Misting system.

High velocity water particles have a significant area of turbulent air around them which makes it difficult for them to impact dust particles. High Pressure Misting with a water discharge velocity of around 200km/hr generally only does a good job suppressing dust at the end of its projection when the speed of the water droplets have reduced. This makes their installation difficult for small spaces such as conveyor transfer points.

High Pressure Misting does have an advantage that the high velocity and larger droplets have more kinetic energy so are less impacted by the wind than Dry Fog droplets which are smaller and low velocity. In applications where the dust source is unable to be protected from the wind (see Dust Tamer Wind Fences) and long throw distances are required (eg > 6m) a High Pressure Misting system may give better dust suppression performance.

For the same water flow (eg. 3 litres per minute) High Pressure Misting has a smaller orifice (eg 80 bar = 0.7mm diameter orifice) compared to Dry Fog (1 bar = 2.1mm diameter orifice). Smaller orifices are more likely to get blocked with sediment or scale build up. Dry Fog systems are usually designed to filter water to 5 micron (0.005mm) so that the larger particles in the water do not impact the dust suppression performance (water droplets average 4 micron).

If water is left in pipes when the system is not operating it increases the likelihood of scale build up. Dry Fog systems are designed to flush the water lines and nozzles with compressed air after use to reduce the risk of scale build up.

The Technologies

The aim of both technologies is to project a cloud of tiny droplets (as close as possible to the dust particle size ) into the air where there is airborne dust. The water droplets in this cloud come into contact with similar sized dust particles and combine. As the combined dust and water particles get larger they impact larger dust particles and other combined dust and water particles until they become heavy enough to fall out of the air. A more detailed discussion of this is included on our Dust Control Theory page.High Pressure Misting Technology

High pressure misting uses water at a high pressure (usually between 80 and 120 bar) pushed through small orifices to create small droplets. It is the same technology used in pressure washers. Droplet sizes are quoted to be around 38 microns (Environmist - p41 Australian Mining Review May 2024).Dry Fog Technology

Dry Fog uses a combination of water and compressed air and a specially designed nozzle which creates an ultrasonic pressure wave which shears the incoming water stream and creates very small droplets. The water pressure is very low (0.5 to 1.5 bar) and the air pressure is also low (5 bar). The nozzles use a high volume of compressed air which has the benefit of giving the fog significant projection and throw distance. The droplet size is around 4 micron for the smallest nozzle. The term Dry Fog is used because the water droplets are so small that the fog does not feel wet.

Dust Suppression Performance

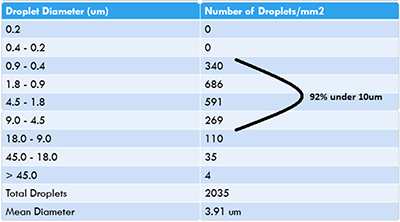

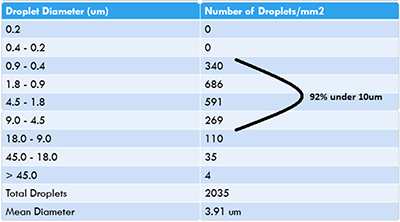

PN2.5 (dust particles less than 2.5 micron) and PN10 (dust particles less than 10 micron) are the most high risk dust particles for human exposure. Dry Fog with an average droplet size of 4 micron and 92% of droplets less than 10 micron is much better at suppressing PN2.5 and PN10 dust than High Pressure Misting with an average droplet size of around 38 micron due to the need for the water droplet and dust particle sizes to align for optimal suppression.For a given volume of water the smaller 4 micron droplet of the Dry Fog also results in 860 times as many droplets with a total surface area 9.5 times as large as the 38 micron droplet of the High Pressure Misting. This results in a significant improvement in dust capture capability particularly in the PN2.5 and PN10 size dust particles. In practice this results in Dry Fog dust suppression systems using significantly less water than a High Pressure Misting system.

High Pressure Misting can appear to do a good job because it suppresses the larger dust particles that are visible to the naked eye. Airborne dust particles less than 30 micron are difficult to see with the naked eye unless they are in high concentrations.

High Pressure Misting does have an advantage that the high velocity and larger droplets have more kinetic energy so are less impacted by the wind than Dry Fog droplets which are smaller and low velocity. In applications where the dust source is unable to be protected from the wind (see Dust Tamer Wind Fences) and long throw distances are required (eg > 6m) a High Pressure Misting system may give better dust suppression performance.

Reliability

System reliability is predominantly a result of nozzle blockages caused by either suspended particles or dissolved particles (ie. scale). Suspended particles can be filtered, but dissolved particles cause build up on surfaces over time and is particularly an issue if lines are left full with water (no flow).For the same water flow (eg. 3 litres per minute) High Pressure Misting has a smaller orifice (eg 80 bar = 0.7mm diameter orifice) compared to Dry Fog (1 bar = 2.1mm diameter orifice). Smaller orifices are more likely to get blocked with sediment or scale build up. Dry Fog systems are usually designed to filter water to 5 micron (0.005mm) so that the larger particles in the water do not impact the dust suppression performance (water droplets average 4 micron).

If water is left in pipes when the system is not operating it increases the likelihood of scale build up. Dry Fog systems are designed to flush the water lines and nozzles with compressed air after use to reduce the risk of scale build up.

Safety

Water that is left in pipelines are at risk of growing waterborne bacteria (such as Legionnaires). This is particularly dangerous if fogged or misted as it can be easily inhaled. Dry Fog systems flush the water lines with compressed air after use which significantly reduces this risk. Wet Earth recommends that if there is a chance that the water source could contain waterborne bacteria then a water sanitisation system (eg. UV Sanitisation) be included in any Dry Fog or High Pressure Misting system.Water discharged at high pressure (80 bar) such as that used with High Pressure Misting can have a very abrasive effect. Care needs to be taken to ensure humans are kept at an appropriate distance from the nozzle tip. Dry Fog with its low water and air pressures do not have this risk.

If you have a particular dust control application you would like to discuss or would like more information then please call us on +61 2 6062 3300 or send an email to sales@wetearth.com.au.